MARELEC Food Technologies designs and manufactures high-tech cutting, weighing, sorting and control systems for the fishery and food industry.

MARELEC Food Technology has been active in the food processing industry since 1983. It manufactures the most important fishing vessel control systems and other electronic marine systems in the shipping world.

Their experience and know-how on fish weighing and sorting systems results in powerful, reliable systems that weigh and classify fish perfectly both on shore and at sea.

The unique features of their systems are the robustness, the high speed, the precision and the customized design, which have been applied equally to poultry and meat systems for many years.

FIXED WEIGHT CUTTING - SORTING - TRIMMING

FIXED WEIGHT CUTTING

The smart way of cutting fixed weight with 1 or 3 cameras for the minimum fira and maximum accuracy.

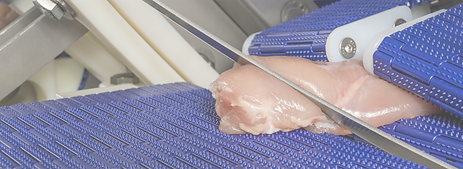

MARELEC PORTIO cuts fresh poultry, meat and fish products into portions of programmed constant weight, thickness or a combination of the two, using high-tech laser and camera scanning.

As a result, it has a high-precision cutting machine at a competitive price.

It can also cut fresh boneless or boneless meat products into portions of programmed constant weight, thickness or a combination of the two.

SCREENING

Sorting & Grouping

MAELEC Grading Solutions technology uses cutting-edge weighing technology and advanced software for accurate and fast product sorting.

This can be for whole fish or fillets, fresh, frozen or vacuum-packed.

For meat, whole, portions or portions, fresh or frozen.

Finally, in poultry in whole or in pieces, fresh or frozen.

MARELEC sorters can be sorted into different sizes on fixed weight discs or in production batches.

All equipment is made based on robustness and high health standards.

'TRIMMING' - TRIMMING

Monitor your performance and capacity

Factors such as performance and capacity are vital to the profitability of a poultry, meat or fish processor.

Trimming lines are systems that help you monitor the capacity and strength of a cutting process.

They are used in many fields (meat, poultry, fish, etc.). They are usually tailored to specific needs, so they come in many different shapes.

MARELEC has now developed a smart cutting line that can monitor performance, capacity and cutting quality per operator.

WEIGHING

Static scales, batch scales & flow scales

MARELEC offers multiple types of weighing solutions.

With a background in the fishing industry, the equipment is produced to high quality standards with an emphasis on speed and accuracy.

The batch weigher is designed to create fixed weight batches consisting of many products and to fill bags, boxes and cartons.

The flow scale is designed to accurately weigh a product flow, e.g. pieces of meat or trimmings, for a specific period of time.

They have an accuracy of <1% with a capacity of 2-100 tons / hour and a conveyor width from 300mm to 800mm.

The use of a flow scale eliminates the need to collect raw material in trays or boats for weighing and provides continuous performance.

Flow scales are always equipped with a Z2 indicator that records weights and communicates with your network system.

MATRIX software can determine and display the rate of return when using multiple flow scales or the combination of a flow scale with a sorter. This performance is a direct KPI (Key Performance Indicator) that can be used to determine if a process (machine / operator) is operating under the best conditions.

CUTTING WITH WATER CUTTING SYSTEM

Fixed Weight Cutting with Water Cut - Waterjet

The MARELEC PORTIO JET is a state-of-the-art water cutter based on more than 15 years of successful experience in constant weight cutting.

The water-cutting system is designed to cut boneless poultry products, such as chicken breast and boneless thighs into predetermined custom shapes, while maintaining constant weights.

Key benefits:

Amazing accuracy

Optimized yields

Smart cutting algorithms

Design capability for maximum capacity

Extremely easy to clean

User friendly software

Touch screen

Separate high pressure pump

The PORTIO JET has been developed to maximize yields when cutting predetermined shapes from poultry fillets or boneless leg meat at constant weights.

The combination of camera and laser scans with the highest accuracy and the smart cutting algorithm calculates the optimal cutting design.

Typical applications include cutting chicken fillets into portions, cubes or strips of constant weight.

Boneless leg meat can be cut and divided into fixed weight portions.

Strips or cubes, such as karaage, kakugiri or BLK, are extremely popular.

PORTIO Cutting Machine 3

Fixed weight cutting - length.

PORTIO 3 is also used in meat applications such as steaks, fillet, rib eye, cubes for meat stew, pork fillet, etc. with vertical cutting at programmed constant weight or length.

PORTIO 3 uses the technology of 3 camera / laser combinations to accurately scan all the meat around the perimeter.

Portio 3 is also available for fish and poultry.

The history of MARELEC

Read the history of MARELEC on their website below to learn about their amazing journey.